Innovative Packaging Solutions For Stability of Drug Formulation

As the pharmaceutical industry continues to grow, so does the need for innovative packaging solutions that provide stability and safety for drug formulations. Innovative packaging solutions not only help to preserve the shelf life of drug products, but also enhance their safety and effectiveness. In this article, we will explore some of the innovative packaging solutions that are being developed to ensure the stability of drug formulations.

The importance of packaging in the pharmaceutical industry cannot be overstated. Proper packaging helps to protect drug formulations from external factors such as moisture, light, and oxygen that can degrade the product over time. Packaging also plays a critical role in ensuring the safety and efficacy of drugs by providing tamper-evident features and child-resistant closures. Innovative packaging solutions are therefore essential in providing the necessary protection and safety for drug products.

Traditional Packaging Solutions

Traditional packaging solutions for pharmaceutical products include glass vials, ampoules, and plastic bottles. These types of packaging are widely used due to their ease of manufacturing and their ability to protect the drug formulation from external factors. However, traditional packaging solutions have some limitations, including the potential for breakage and the inability to prevent moisture ingress.

Innovative Packaging Solutions

Desiccant Packaging

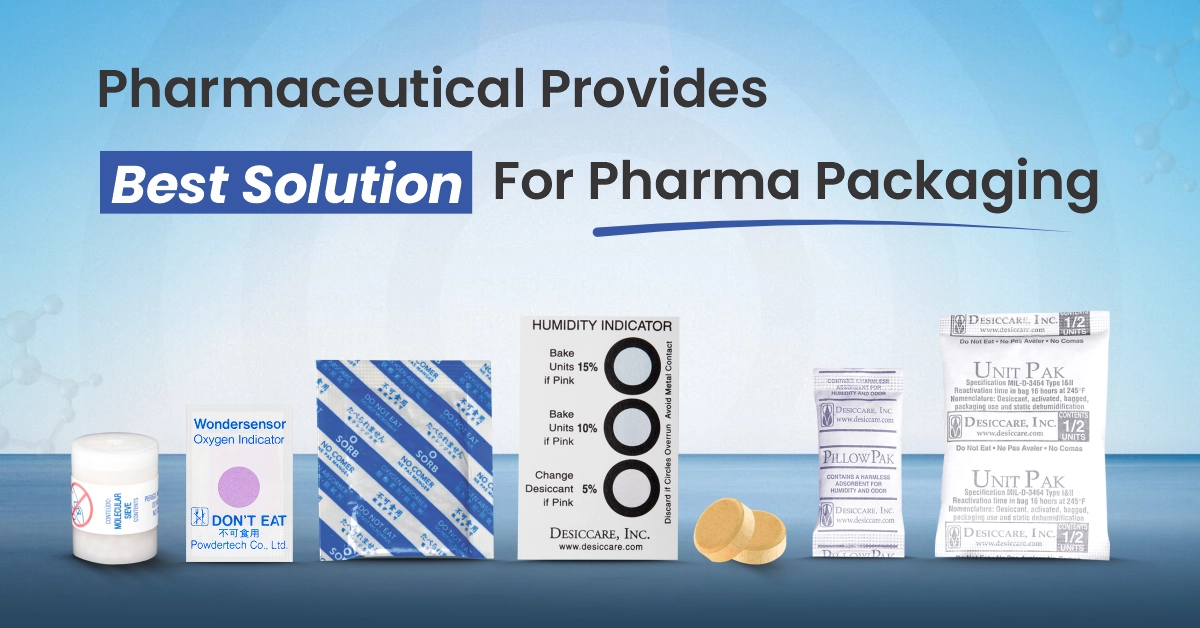

Desiccant packaging is an innovative solution for protecting drug formulations from moisture. Desiccant packets are placed inside the packaging to absorb moisture and prevent it from affecting the drug product. This type of packaging is particularly useful for drugs that are sensitive to moisture, such as antibiotics and steroids.

Modified Atmosphere Packaging

Modified atmosphere packaging is another innovative solution that is being used to preserve the stability of drug formulations. This type of packaging involves the use of a special gas mixture that is designed to reduce the oxygen content in the package. This helps to prevent the oxidation of the drug formulation and prolong its shelf life.

Blister Packaging

Blister packaging is an innovative solution that provides both protection and convenience for drug products. This type of packaging involves the use of a plastic or aluminum foil blister that is sealed to a cardboard backing. The drug product is placed inside the blister, which is then sealed to prevent tampering. Blister packaging is particularly useful for drugs that are taken in small doses, such as tablets and capsules.

Smart Packaging

Smart packaging is a new and innovative solution that incorporates electronic sensors into the packaging. These sensors can detect changes in temperature, humidity, and light, and provide real-time feedback to the manufacturer and end-user. This type of packaging is particularly useful for drugs that require strict temperature control, such as vaccines and biologics.

Conclusion

Innovative packaging solutions play a critical role in ensuring the stability and safety of drug formulations. Desiccant packaging, modified atmosphere packaging, blister packaging, and smart packaging are just a few examples of the innovative solutions that are being developed to meet the needs of the pharmaceutical industry. As the industry continues to grow and evolve, so will the need for new and innovative packaging solutions.

FAQs

Q1. What is the role of packaging in the pharmaceutical industry?

Packaging plays a critical role in protecting drug formulations from external factors such as moisture, light, and oxygen that can degrade the product over time. Packaging also provides tamper-evident features and child-resistant closures to ensure the safety and efficacy of drugs.

Q2. What are some traditional packaging solutions for pharmaceutical products?

Traditional packaging solutions for pharmaceutical products include glass vials, ampoules, and plastic bottles.

Q3. What is desiccant packaging?

Desiccant packaging involves the use of desiccant packets to absorb moisture and prevent it from affecting the drug product. This type of packaging is particularly useful for drugs that are sensitive to moisture.

Q4. What is blister packaging?

Blister packaging involves the use of a plastic or aluminum foil blister that is sealed to a cardboard backing. The drug product is placed inside the blister, which is then sealed to prevent tampering. Blister packaging is particularly useful for drugs that are taken in small doses, such as tablets and capsules.

Q5. What is smart packaging?

Smart packaging is a new and innovative solution that incorporates electronic sensors into the packaging. These sensors can detect changes in temperature, humidity, and light, and provide real-time feedback to the manufacturer and end-user. This type of packaging is particularly useful for drugs that require strict temperature control, such as vaccines and biologics.

Q6. How do innovative packaging solutions benefit the pharmaceutical industry?

Innovative packaging solutions help to preserve the stability of drug formulations, enhance their safety and efficacy, and provide convenience for the end-user. They also help to reduce waste and improve the overall efficiency of the pharmaceutical supply chain.